Eureka Wearmax Grinding Industries Inc. is comprised of 3 distinct divisions: Eureka Tool Steel Welding Products, Ltd., Eureka Grinding Industries, Ltd. and Eureka Wearmax Plate div. Please take a moment to browse through the services that each of our divisions has to offer.

Wearmax is a superior abrasion resistant alloy clad plate which was developed to address the inherent problems associated with the multitude of wear factors in industry use. With 75 years of experience in the mixing and formulating of hard-surfacing welding wires, Eureka Wearmax Grinding Industries Inc. has been able to develop the technology of bulk welding to the ultimate degree possible.

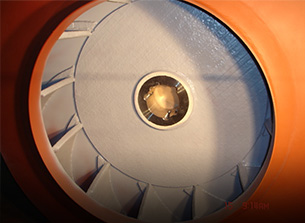

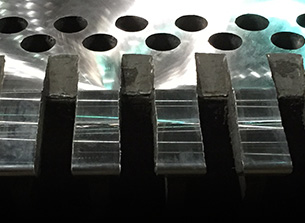

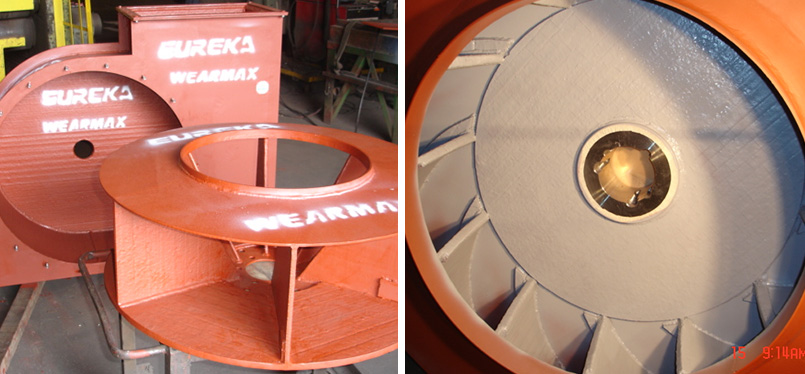

The Wearmax process, developed by Eureka Wearmax Grinding Industries Inc. utilizes three major components in its production; a granulated metal alloy powder, a weld wire consumable and a specific chemistry carbon steel base plate. Under the Wearmax method a submerged arc welding process is utilized to fuse the metal alloy powder to the base plate, resulting in a smooth carbide overlay rich in chrome.

The wear resistant side of Wearmax plate appears as smooth wide weld beads running the length of the plate. During the welding process, stress relief cracks (cross checks) develop at right angles to the weld beads but only in the carbide overlaid layer. This is a characteristic of hard facing due to the co-efficient of expansion between the hardface layer and the carbon steel base plate. This cross checking is desirable in the forming of the Wearmax plate into curved shapes without damage to the overlay.

Industry Applications:

Mining

- Chutes

- Crusher liners

- Loading pocket liners

- Truck bed liners

- Shovel liners

Steel

- Skip car liner plates

- Sinter plant fans

- Plate mill guides

- Blast furnace chutes

- Blast furnace hanging armour plates

Cement

- Impact Plates

- Clicker chutes

- Silo liners

- Classifier cones

Pulp and Paper

- Cyclone liners

- Bark chutes

- Drag conveyors

Coal Burning Power Plants

- Fan blades

- Chute and hopper liners

- Dust handling systems